Winter is very nearly upon us, and as today was still relatively warm (high forties, F) I took a few minutes to whip up one of the secondary projects for this machine.

I mentioned before wanting to replace the collet tray that came with it:

The slides, judging from photos of other machines online, are factory, but the wood plate is some shop-made replacement. The factory one, I think, appears to hold 37 collets, and has a selection of smaller holes for things like allen wrenches and turret tooling.

I suspect the original got damaged years ago, and somebody swapped in this one- with fewer holes, which are too tight, and fewer of them. Between the tight holes, the slightly erratic spacing, and the too-thin wood, as well as the limited use of space, I've wanted to replace it since the thing rolled into the shop.

So, to use up one of the last reasonably warm days of the year- since I have to do some of this work outside- I got out a leftover chunk of some sanded cabinet ply I had laying about.

I cut a section the same width but a few inches longer than the old piece, and then did a little playing about with spacings to see how many collets I could jam in there.

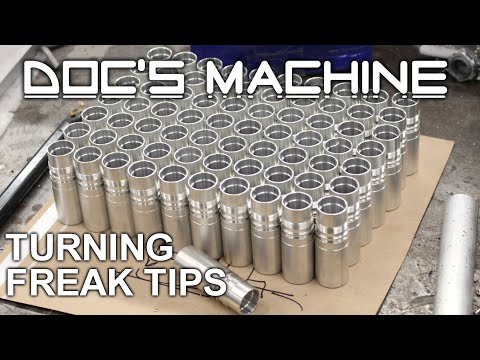

Turns out, with a little luck, I was able to fully double the density of the old tray, and fit forty-eight collets in there. These I laboriously cut out with a holesaw- laboriously as I had to stop after each one and pry the waste disc out with a screwdriver.

Using a small-radius roundover bit on the router (the one that came as the spindle for my Shapeoko ) I smoothed up the edges of each hole, as well as the outer edges of the whole sheet. After that, I sanded everything thoroughly with 220 grit and blew it off with compressed air.

) I smoothed up the edges of each hole, as well as the outer edges of the whole sheet. After that, I sanded everything thoroughly with 220 grit and blew it off with compressed air.

And finally- at least, it was all I could do this evening- I have it a quick wipe with some stain, and set it aside to dry.

When it's dry in the next day or two, I'll hit it with a couple coats of rattle-can poly clear. And once that's dry... that's pretty much it. It's done.

Doc.

I mentioned before wanting to replace the collet tray that came with it:

The slides, judging from photos of other machines online, are factory, but the wood plate is some shop-made replacement. The factory one, I think, appears to hold 37 collets, and has a selection of smaller holes for things like allen wrenches and turret tooling.

I suspect the original got damaged years ago, and somebody swapped in this one- with fewer holes, which are too tight, and fewer of them. Between the tight holes, the slightly erratic spacing, and the too-thin wood, as well as the limited use of space, I've wanted to replace it since the thing rolled into the shop.

So, to use up one of the last reasonably warm days of the year- since I have to do some of this work outside- I got out a leftover chunk of some sanded cabinet ply I had laying about.

I cut a section the same width but a few inches longer than the old piece, and then did a little playing about with spacings to see how many collets I could jam in there.

Turns out, with a little luck, I was able to fully double the density of the old tray, and fit forty-eight collets in there. These I laboriously cut out with a holesaw- laboriously as I had to stop after each one and pry the waste disc out with a screwdriver.

Using a small-radius roundover bit on the router (the one that came as the spindle for my Shapeoko

) I smoothed up the edges of each hole, as well as the outer edges of the whole sheet. After that, I sanded everything thoroughly with 220 grit and blew it off with compressed air.

) I smoothed up the edges of each hole, as well as the outer edges of the whole sheet. After that, I sanded everything thoroughly with 220 grit and blew it off with compressed air.

And finally- at least, it was all I could do this evening- I have it a quick wipe with some stain, and set it aside to dry.

When it's dry in the next day or two, I'll hit it with a couple coats of rattle-can poly clear. And once that's dry... that's pretty much it. It's done.

Doc.

Comment