Announcement

Collapse

No announcement yet.

What did you 3D print today?

Collapse

X

-

I've been eyeballing the x1c. Mainly because my ender 3s are making me depressed lol, how is that bambu?

-

-

This fit tight on my cat, and forcing it on cracked it to death... ugh,9 ours gone. I dunno what my issue is, but I'll spend speckled parts of my free time trying to get it working.

I'm about ready to scrap both of my printers and buy a more modern one. My buddy bought a creality K1, and he is printing 10x faster than me with 100x less issues out of the box. I've struggled to print anything at 30mm/s since day one, and I've tossed upgrades at these things the whole time.

-

Found a remixed duct for my aftermarket printer head assembly. It gives much more clearance from my print. Printing the clamping block for the above grip now with better part cooling.3 Photos

- Likes 1

Leave a comment:

-

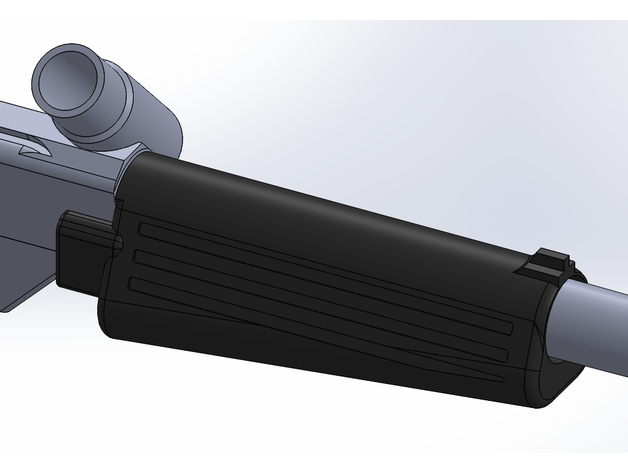

Finally got a part off my printer. Icd cat foregrip, not my design. It was on thingiverse. It makes a cat so comfy and can be used on other shooters like pro carbs.

it's not great, but I'll take it. Inland petg .2 layer height, no cooling. My duct kept snagging the print so I pulled the ducts and printed this. I think the lack of minor cooling caused the zitty over hangs, but they honestly add grip so it's no biggie. My friend made me the same handle on his creality K1. And it's much nicer.

Foregrip for any of the Indian Creek Design "Cat" paintball guns (Thunder Cat, Alley Cat, Bobcat, Puma). Modeled after the Tippmann “Pro” series foregrip (Pro/Carbine, Pro-Lite, Pro-Am, F/A). It clamps to the 1" OD section of the upper receiver. Requires 10-32 x 1/2" socket head cap screws and 10-32 nuts, 2 each.I suggest printing with a raft for bed adhesion. The clamp piece should be printed with a relatively high infill density. The foregrip can be done with a medium infill density.

Foregrip for any of the Indian Creek Design "Cat" paintball guns (Thunder Cat, Alley Cat, Bobcat, Puma). Modeled after the Tippmann “Pro” series foregrip (Pro/Carbine, Pro-Lite, Pro-Am, F/A). It clamps to the 1" OD section of the upper receiver. Requires 10-32 x 1/2" socket head cap screws and 10-32 nuts, 2 each.I suggest printing with a raft for bed adhesion. The clamp piece should be printed with a relatively high infill density. The foregrip can be done with a medium infill density.

Printing a new lower profile duct for my MAD now out of the same material. Hoping it doesn't clip prints. Then I'll print the clamp shoe for this grip.4 Photos

- Likes 3

Leave a comment:

-

I like the texture on it though. I think Plasti-Dip would dull the texture.

-

The Great Equalizer I'm not sure just yet. The sizing of this AC threaded body is a little odd. The threaded section is like 1.1" OD and I couldn't find pump handles to fit, necessitating a custom one.

Also this one isn't designed around the stock trracer feedneck. I'm not against a redesigned version for stock trracers, but I need to pick up a body to get proper measurements.

Let me iron out my current issues and we can talk.

-

Thanks for the answer to my previous questions. I have set of Staunchy barrel adapters for a Trracer, but I haven't gotten around to getting a pump arm to fit an AC barrel yet. Are you going to be selling these?

Leave a comment: