Announcement

Collapse

No announcement yet.

What did you 3D print today?

Collapse

X

-

Love my brass ... Love my SSR ... Hard choices ...

XEMON's phantom double sided feed

Keep your ATS going: Project rATS 2.0

My Feedback

- Likes 1

Comment

-

Love my brass ... Love my SSR ... Hard choices ...

XEMON's phantom double sided feed

Keep your ATS going: Project rATS 2.0

My Feedback

- Likes 1

Comment

-

My daughter's Black and Decker blender stripped the drive, which was plastic on top of being poorly designed. They don't seem to have any around the intarwebz, so I drew one up and printed it in PETG. It has actually started making smoothies. I half-way expected it to explode and go back to try nylon, but not yet.

08/14/21 - still making smoothies.

Last edited by Spider!; 08-14-2021, 07:21 PM.

Comment

-

- Likes 3

Comment

-

Love my brass ... Love my SSR ... Hard choices ...

XEMON's phantom double sided feed

Keep your ATS going: Project rATS 2.0

My Feedback

Comment

-

I've seen some self-centering conveyor belts and stuff, but I just think it's crazy that they'd rely on a stop of some sort for a drive belt, like they expect unbalanced pressure on that side. But, you know the machine much better than I do. So good luck. Hopefully it's an easy fix.

-

I've worked on conveyer system a bit (bottled water) and this is the junkiest system ... But the carriage is about an ounce and has 10" travel distance ... Higher end printers use linear rails, but still keep this belt system. Just thinking a dot of glue might be enough to help it not slip out of the slot ...

PS: it's hard to work on industrial grade equipment all day and come home and work on the most basic and archaic system 😅

-

Oh nice. I do maintenance in a rubber factory, and used to work in a bread factory. I feel ya with the janky home contraptions. The disregard for industrial standards irks the hell out of me. Lol

-

-

- Likes 8

Comment

-

Spider! a lot of them are going to these guys:

I acquired a decent size lot of Armson guns a couple months ago. The lot consisted of Armson Paintball Rifles and Armson Semi paintball guns. I have spent most of the time since cleaning/repairing, finding parts and learning a lot about these guns. You might see them on eBay, but obviously contact me here if you have any

-

Attempting to get her running after my hero me install. Trying vup holder reducers for my wifes car. I think my filament is bad its been on my printer in my basement climate for a few months while this was sidelined. I cant seem to get it, to extrude evenly to save my life. and once i leave a curl, the left cooling duct snags it.

Im gonna let it run even with the crap first layer and hope my dual fans let me bridge the middle layers up enough to make it usable. Either way i think Im tossing this filament after the attempt.1 Photo

Comment

-

Yeah, I was fixong to to a board much like yours, but my co worker explained it was a bad idea as you can have issues with thermocouple readinds when you run them through a board. So he said, "You are stuck with the TC wires straight through, why make a breakout for the rest?"

Seems to work for you, but being I still dont get great prints as it is, I didnt wanna add to it. Lol.

That being said, we split a plug kit, so standard fans can simply be plugged in. I did a single male for the cold end fan, and single male for the part cooling. Then i cut up the wires from a cpu cooler I upgraded, and made a y harness that is single female to duap male plugs for swapping between single or dual fan sey ups.

Not as easy as your BO board, but rairly easy to swap fans now.

-

Sounds good, i was concerned about the TC too but it works perfectly.

I hate plugs for small stuff ... I needed to add a fan the other day and just zip tied it to the carriage and hocked it up in parallel to the hot end cooling fan, works for me ...

Didnt thought about mining plugs around to fit.

PS: Your lightup fan looks cool, how does it work?

-

Light up fan seems to be at an equivelant to the stock fan, but it is quieter. I got 4 of them for 15 bucks or so shipped, so even if I get a junker they should be of a good value. Let me run it for some time and Ill let ya know how they last.

-

-

Making a cup holder reducer for my wifea car and her Yerbae cans.

Also Xemon, here is my plug assemblies.2 Photos

Comment

-

Im not sure how bad the creep is. That cup holder looks pretty nice, printed at 225 nozzel temp, i checked the cold end with my finger mid print, and its slightly warm, but cooler to the touch. Id have to pull my filament after a print to see how creep is. I did have a nozzel jam last night, but it was my last creality branded nozzel, and swapping it gave me a night and day better print.

Edit: unless ya have any tips for identifying heat creep. I do have an IR gun I could check it with.

-

Well ... If i retract the recommended 6mm the filament get stuck into the heat break ...

When i swapped to the HeroMe, i replaced the main fan with a 40X40X20 and a titanium heat break ...

3mm to 2.5mm retraction works great ...

I f i didn't hate water-cooled system so much, i would probably give a go to water-cooled hot end ...

-

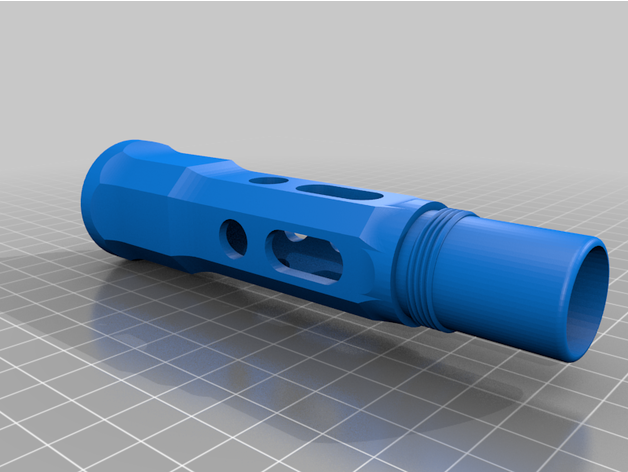

Stubby freak barrel for the Thumper. Thank you JonM - I used the dimensions of your 8 inch freak barrel as a starting point. Modeled it to kinda mirror the feed tube milling.

Rainmaker's feedback: https://www.mcarterbrown.com/forum/b...maker-feedback

Rainmaker's feedback: https://www.mcarterbrown.com/forum/b...maker-feedback

- Likes 10

Comment

-

Love my brass ... Love my SSR ... Hard choices ...

XEMON's phantom double sided feed

Keep your ATS going: Project rATS 2.0

My Feedback

- Likes 2

Comment

Comment