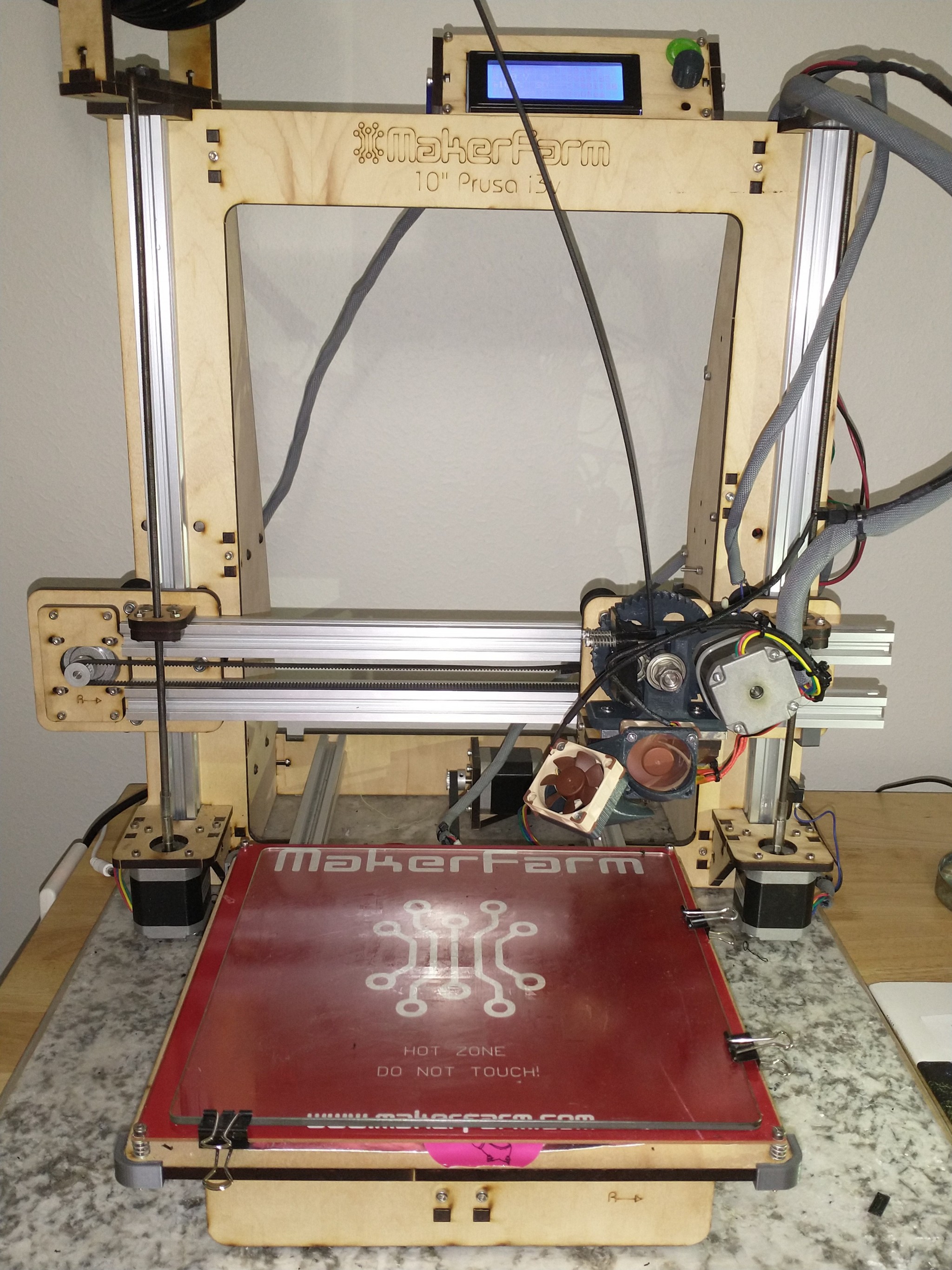

I have spent another couple of months farting around with my old makerfarm printer. Since my son bought, built-it, used it for a while, then left it with me, I have slowly gotten into its inner workings. I still haven't tried to tinker with the programming. It's pretty educational, and I keep a newer Prusa for when I need a part within common parameters and no fuss.

Earlier in the year, I bought a 0.5mm, steel E3D NozzleX for it, since I use the printer for odd filaments and large prints that require less detail. Last month I bought some 3DXtech PLA+Carbon Fiber to use on it. I could not get it to print beyond about 6 layers, but they were pretty layers. I went back to a roll of IC3D plain PLA that had given me trouble and fought with that for a while.

In the process I learned I was over-extruding, due to the drive bolt I had installed with a larger hobbed diameter (20%). I also found that when I installed the nozzle, it was only tight against the heat block and not on the heat break, so it could leak a little.

The odd thing I found was that I had a full metal hot-end, and it responded to "seasoning" which is the practice of putting a light coating of vegetable oil on the filament to keep it from sticking, especially PLA. It actually worked, and I can't see anything in the print from it either. I was able to finish my superbolt tube feed in PLA+CF, which came out nice.

https://www.mcarterbrown.com/forum/c...724#post330724

Here's another sample of that filament. It is advertised as a nice surface finish and I have to agree. It is also significantly stiffer than PETG, so I'll be picking between the two for different parts.

I also learned that Slic3r has a known bug where the auto-supports come out in whatever layer height it calculates, regardless of printer and slicing settings. Not only is this bad for my low-res steppers, but it is really bad on filled filament that doesn't like 0.08mm layers. I ended up building my own supports for my tube feed.

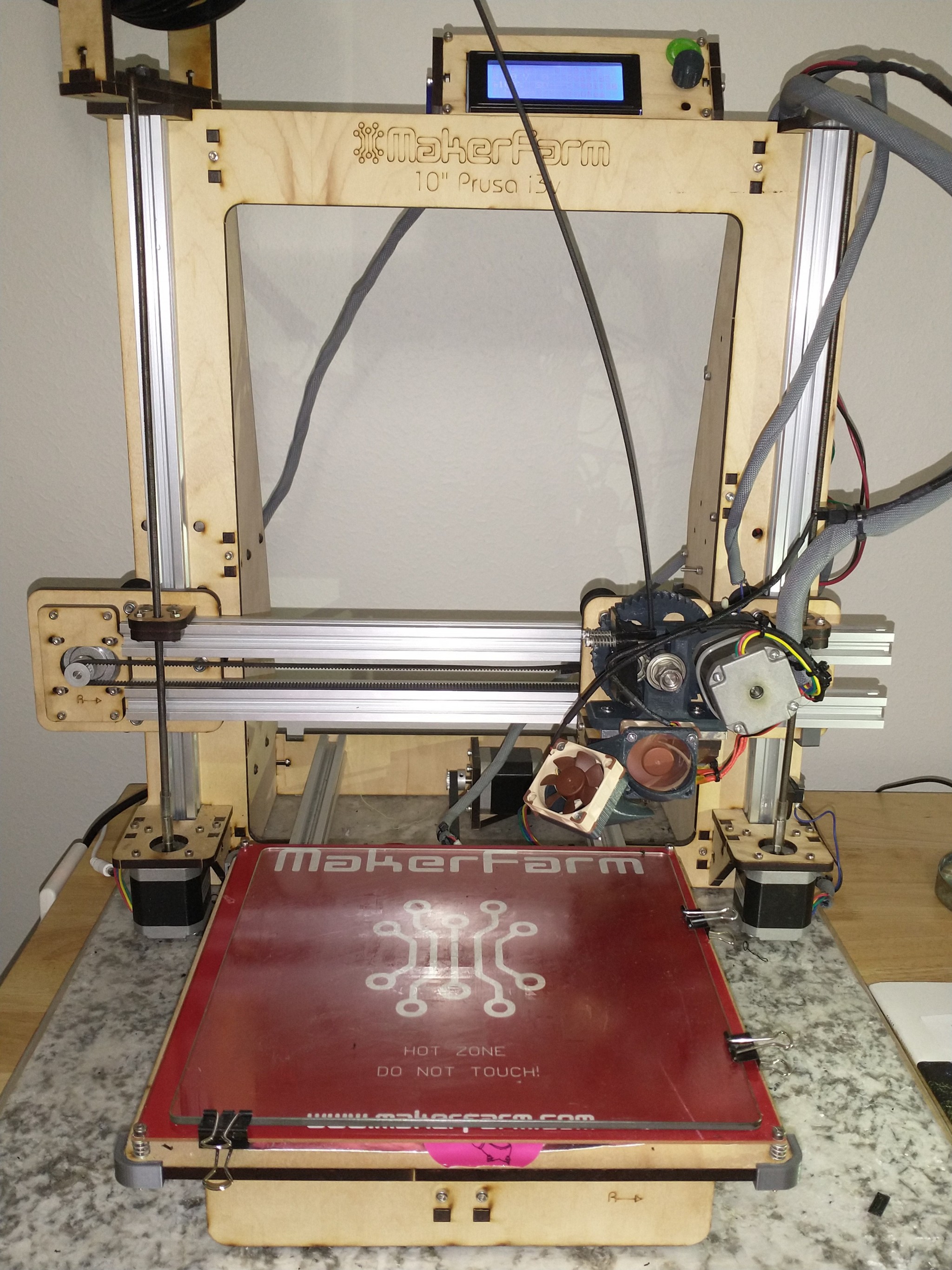

Earlier in the year, I bought a 0.5mm, steel E3D NozzleX for it, since I use the printer for odd filaments and large prints that require less detail. Last month I bought some 3DXtech PLA+Carbon Fiber to use on it. I could not get it to print beyond about 6 layers, but they were pretty layers. I went back to a roll of IC3D plain PLA that had given me trouble and fought with that for a while.

In the process I learned I was over-extruding, due to the drive bolt I had installed with a larger hobbed diameter (20%). I also found that when I installed the nozzle, it was only tight against the heat block and not on the heat break, so it could leak a little.

The odd thing I found was that I had a full metal hot-end, and it responded to "seasoning" which is the practice of putting a light coating of vegetable oil on the filament to keep it from sticking, especially PLA. It actually worked, and I can't see anything in the print from it either. I was able to finish my superbolt tube feed in PLA+CF, which came out nice.

https://www.mcarterbrown.com/forum/c...724#post330724

Here's another sample of that filament. It is advertised as a nice surface finish and I have to agree. It is also significantly stiffer than PETG, so I'll be picking between the two for different parts.

I also learned that Slic3r has a known bug where the auto-supports come out in whatever layer height it calculates, regardless of printer and slicing settings. Not only is this bad for my low-res steppers, but it is really bad on filled filament that doesn't like 0.08mm layers. I ended up building my own supports for my tube feed.

Comment